The application of

rolling shear blade is extremely extensive, mainly concentrated in industries that require large-scale and efficient processing of thin to medium thick plates:

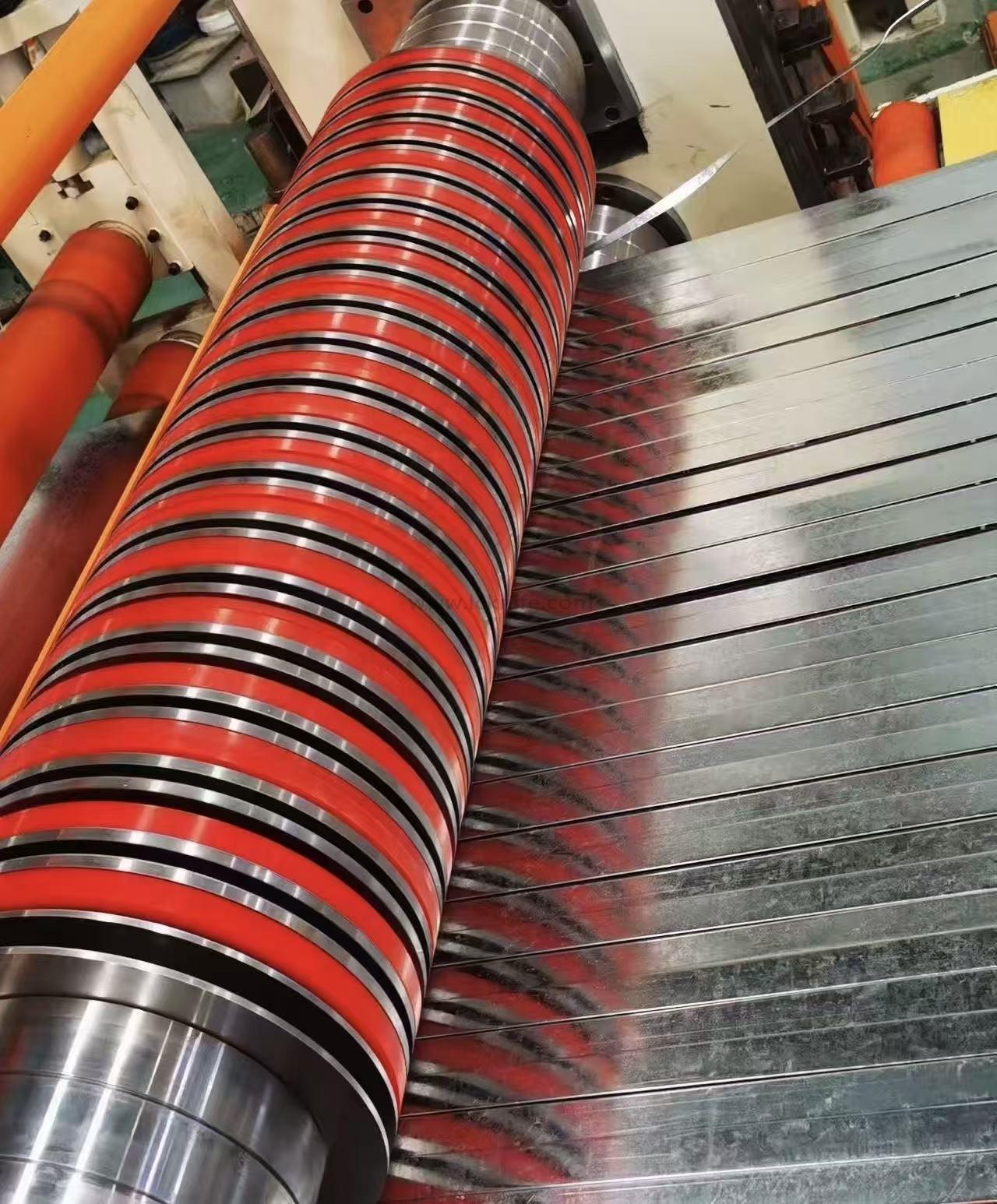

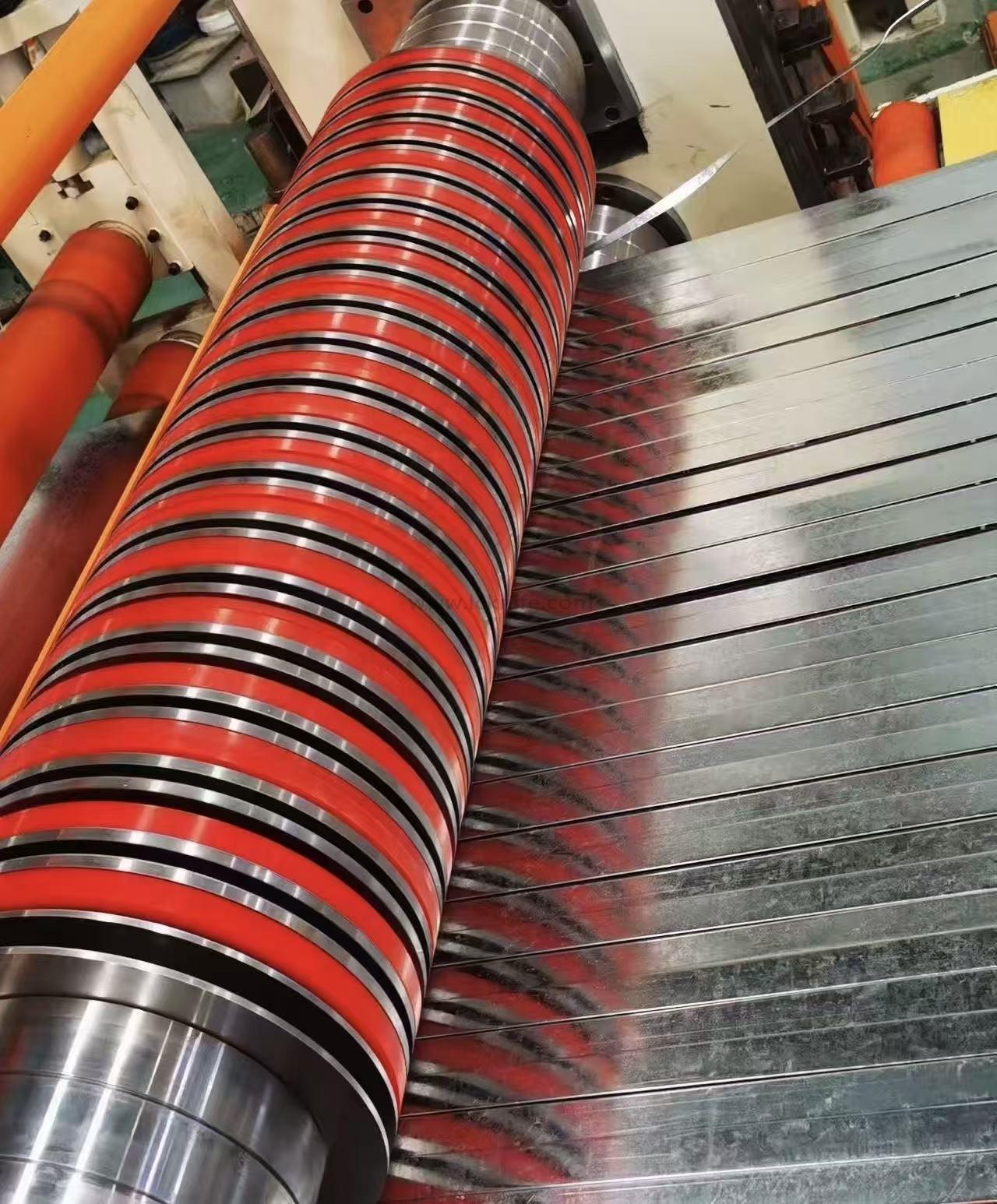

·Metallurgical steel rolling industry: This is the most traditional application field of rolling shear blade. Used for longitudinal cutting and slitting of wide steel coils produced by rolling, cutting them into multiple narrow coils of the desired width; Or perform edge cutting to remove irregular parts of the board edges.

·Metal product processing: When producing products such as louver panels, ceiling joists, cable trays, guardrail panels, etc., it is necessary to divide the roll material into strips before molding, and rolling cutting is an essential preceding process.

·Automotive manufacturing industry: used for cutting metal sheets such as car body panels and internal structural components.

·Aerospace industry: cutting aluminum alloys, titanium alloys and other aerospace materials.

·Home appliance manufacturing industry: used for processing the outer shell panels of household appliances such as refrigerators, washing machines, and air conditioners.

·Packaging and Printing Industry: Used for cutting packaging materials such as tinplate, aluminum foil, cardboard, etc.

The significant advantages of roll

slitter blade

Compared with traditional punching, laser cutting, or plasma cutting, rolling cutting has irreplaceable advantages:

1. High efficiency and continuity: Its continuous rotation cutting method is extremely fast, especially suitable for large-scale coil processing, and the production efficiency far exceeds that of stepper cutting equipment.

2. High precision and high quality: Modern high-precision rolling shear machines can strictly control the width tolerance of the strip (up to ± 0.05mm or even higher), and have good shear section quality, small deformation, and fewer burrs, which is conducive to subsequent processing.

3. Flexibility:

·Width adjustment: By adjusting the axial position of the cutter head, the width of the dividing strip can be easily changed.

·Curve cutting: Through numerical control (CNC) technology, the upper and lower cutter heads can move along a predetermined trajectory during the cutting process, enabling complex curve cutting.

4. Low consumables and energy saving: Compared to high energy consuming equipment such as laser cutting, rolling cutters have lower power consumption. After the blade wears out, it usually only needs to be reground at the edge to be reused, and the cost of use is relatively low.

5. High degree of automation integration: It is easy to connect with equipment such as uncoiler, leveler, feeding device, and rewinder to form a fully automated sheet metal processing production line.

The application of rolling shear blade is extremely extensive, mainly concentrated in industries that require large-scale and efficient processing of thin to medium thick plates:

The application of rolling shear blade is extremely extensive, mainly concentrated in industries that require large-scale and efficient processing of thin to medium thick plates: