In the vast world of material processing, the slitter knife stands as a paramount tool, facilitating precise cutting and slicing of various materials. Whether it's a thin sheet of metal, paper, plastic, or even fabric, the slitter knife plays a vital role in ensuring accurate and efficient processing.

Slitter knives are integral to industries dealing with large-scale material processing. They are responsible for converting bulk rolls of materials into smaller, more manageable sizes, enabling further processing or end-user requirements. Slitter knives find applications in a wide range of sectors, including but not limited to metalworking, packaging, printing, textiles, and plastics. Their precise cutting capabilities help meet the quality standards required for these industries, ensuring consistency and uniformity in the manufactured products.

Design and Construction:

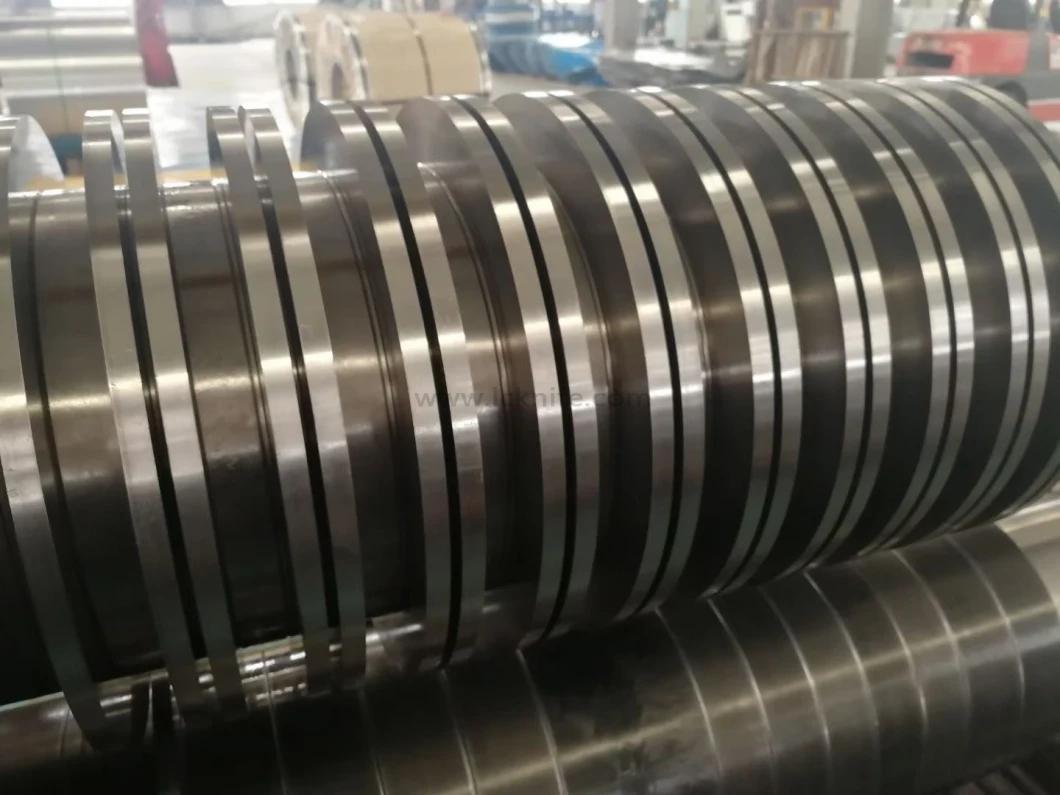

Slitter knives come in various designs and configurations, depending on the material being processed and the specific requirements of the application. Generally, they consist of a sharp, circular blade made from high-quality tool steel or tungsten carbide, which ensures durability, longevity, and resistance to wear and tear. The blades are mounted onto a slitting machine, along with proper tension control, precision guides, and adjustment mechanisms, allowing for precise control of the cutting process.

Functionality and Operation:

Slitter knives operate through a combination of rotary and linear motion, delivering accurate cuts with minimal material wastage. The material to be slit is passed through the slitting machine, guided by precision rollers and tension control mechanisms. As the material advances through the machine, the slitter knife spins rapidly, slicing through the material with precision. The blade's sharpness, combined with proper alignment and tension control, ensures clean cuts and prevents material defects, such as burrs or edge damage.

Applications of Slitter Knives:

The versatility of slitter knives allows them to be employed across various industrial applications. In metalworking, slitter knives are used to cut thin metal sheets into strips for fabrication, stamping, or roll forming processes. In the packaging industry, they are essential for slitting large rolls of packaging materials, such as plastic films, to create smaller rolls or sheets for use in food packaging, labeling, or lamination. The printing industry relies on slitter knives to cut paper, cardboard, or flexible packaging materials into various dimensions for books, labels, or packaging. Additionally, slitter knives find importance in textiles, where they are used to cut and slit fabrics, ensuring accuracy in garment manufacturing and textile processes.

Conclusion:

The slitter knife stands as an indispensable tool in material processing industries, enabling accurate and efficient conversion of large rolls of materials into smaller, more manageable sizes. Its precise cutting capabilities, combined with proper tension control and alignment mechanisms, ensure consistent and uniform results, meeting the quality standards required in various applications. From metalworking to packaging, printing to textiles, the importance of slitter knives cannot be understated. As technology continues to advance, slitter knives are being further optimized to meet the evolving demands of modern industrial processes, making them an essential component for precision material processing.

Tags :

Scan to wechat: