The single shaft shredder blade is one of the most essential components in a single shaft shredder, mainly responsible for cutting and shredding materials. A single axis shredder is a commonly used equipment for the pretreatment of waste plastics, rubber, wood, paper, electronic waste, and other materials. The performance of its blades directly affects the shredding efficiency, service life, and adaptability of the equipment in handling materials.

The blade of a single axis shredder is usually installed on a rotating spindle, and is matched with a fixed blade or spacer fixed on the inner wall of the equipment. Through the rotation and mutual shearing of the spindle, the material is forcefully torn and cut. This type of blade is generally made of high-strength alloy steel or high-speed steel to improve its wear resistance and impact resistance. In long-term high-intensity work, good blade material can effectively extend the replacement cycle and reduce maintenance costs.

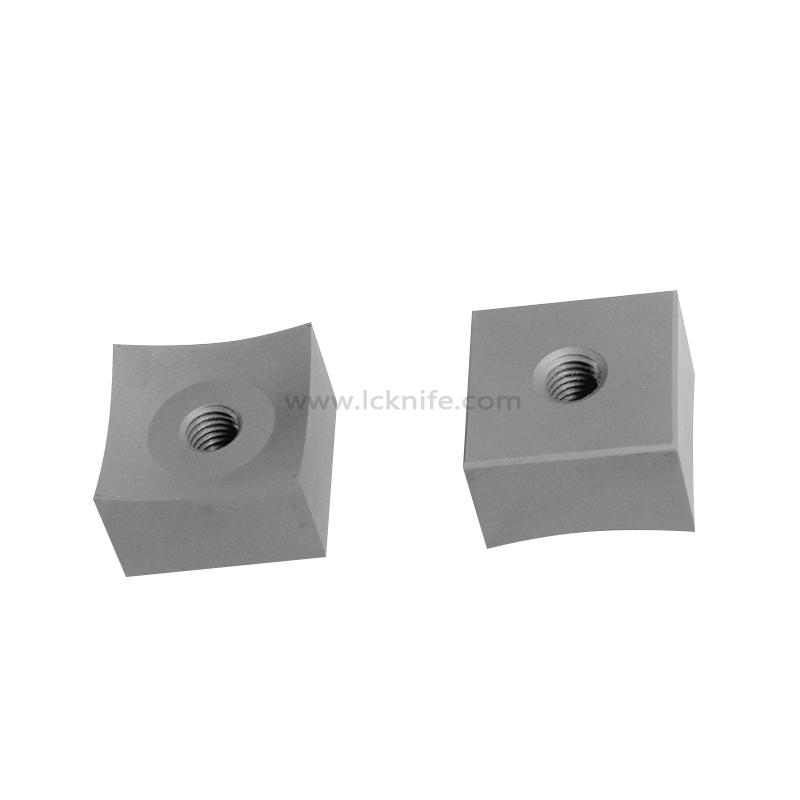

In addition, the structural design of the single shaft shredder blade is also crucial. Common blade shapes include hook, claw, or tooth shapes, and the design emphasizes cutting force and self-cleaning ability to prevent material entanglement or blockage. Different blade types are suitable for materials of different materials, such as metal, plastic, or fiber materials, which may use blades with different angles, tooth numbers, and arrangements.

Scan to wechat: